60,000 sets

per year

8

production line

37,270 ㎡

workshop

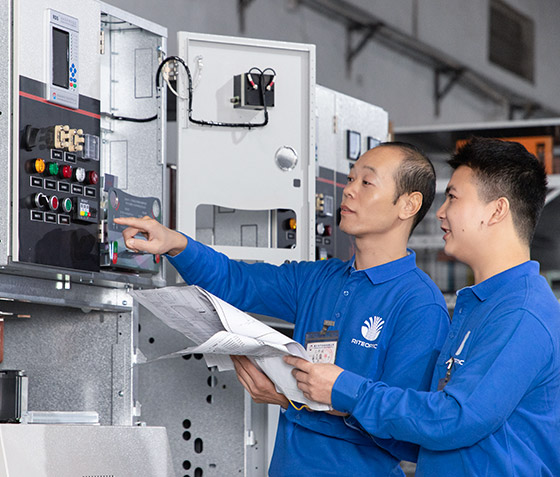

01

Riteoptic makes sure the raw material is bent to the exact dimensions as required. We use tools and grooves of specific thickness to prevent collision with the cabinet product and get the best outcome possible.

02

To get one resistant welded piece, professional technicians mark location guides on the material beforehand and take a delicate control over the timing of when to pre-press and press, how long to press and so on.

03

To produce switching power supply of high quality and stable performance, we apply reliable management to the embedded switching power supply system assembling process, from raw material inspection to finished product test.

In this way, we can minimize the affect of uncertain factors, improve the feasibility of design, and produce safe & reliable 48V power supplies which are waterproof, anti-thunder, and anti-shock for communication stations.

04

Experienced assembly workers combine each part of the rack or cabinet into one complete unit with high efficiency. All finished products will be fully inspected for quality measurement and performance testing.

500,000 km

per year

13

production line

4,000 ㎡

workshop

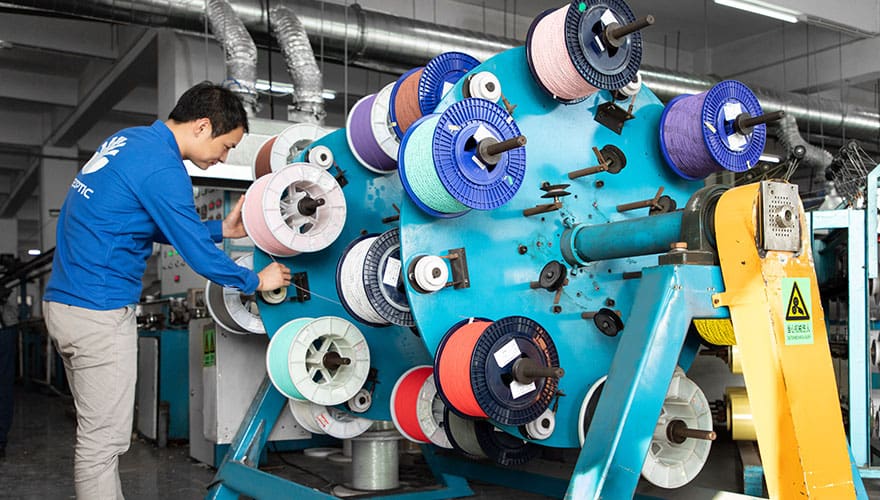

01

Employing the UV curing technology to coat the optical fiber various, bright, and stable colors as well as smooth surface allows workers to recognize different kinds of fibers easily in manufacturing and using.

After the coloring treatment, the colors coated on the optical fibers won't migrate, fade, dissolve in grease, or cause attenuation to the optical fiber.

02

Equipped with the fully automatic cable storage device, our production line can keep non-stop operation even if the optical cable take-up is interuptted by reel change and inspection.

With the tension of optical fiber, the cable storage rack will automatically store the produced optical cable, which will improve production efficiency and stability of the optical cable.

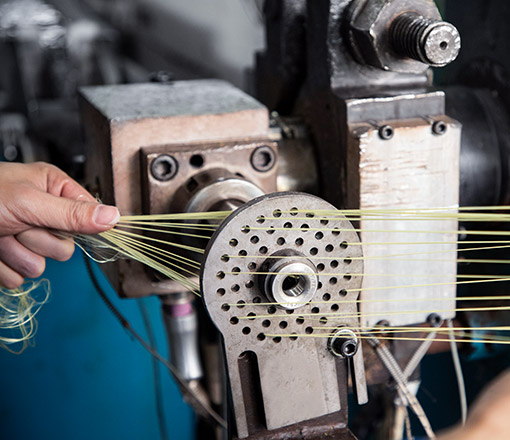

03

In the manufacturing process of optical cable, aramid yarn is widely acknowledged as the most important component, a superior cable reinforcement material.

It is characterized by low density, very high tensile modulus, high fracture strength and substitution of elongation at break.

Moreover, it can maintain inherent stability, low shrinkage, low permissible creep, and very high glass transition temperature at higher temperatures.

In addition to high corrosion resistance, non-conductive, it boast high resistance to most chemicals, except strong acids and strong base.

04

By employing the branded OTDRs of higher accuracy to conduct all the tests, RITE guarantees all optical fibers from its factory will be qualified.

Based on the optical signals reflected by the OTDR at different attenuation points and breakpoints in the fiber are detected by the device, we can calculate the actual length of the optical fiber to quickly weed out the optical fibers with breakpoint or the splicing.